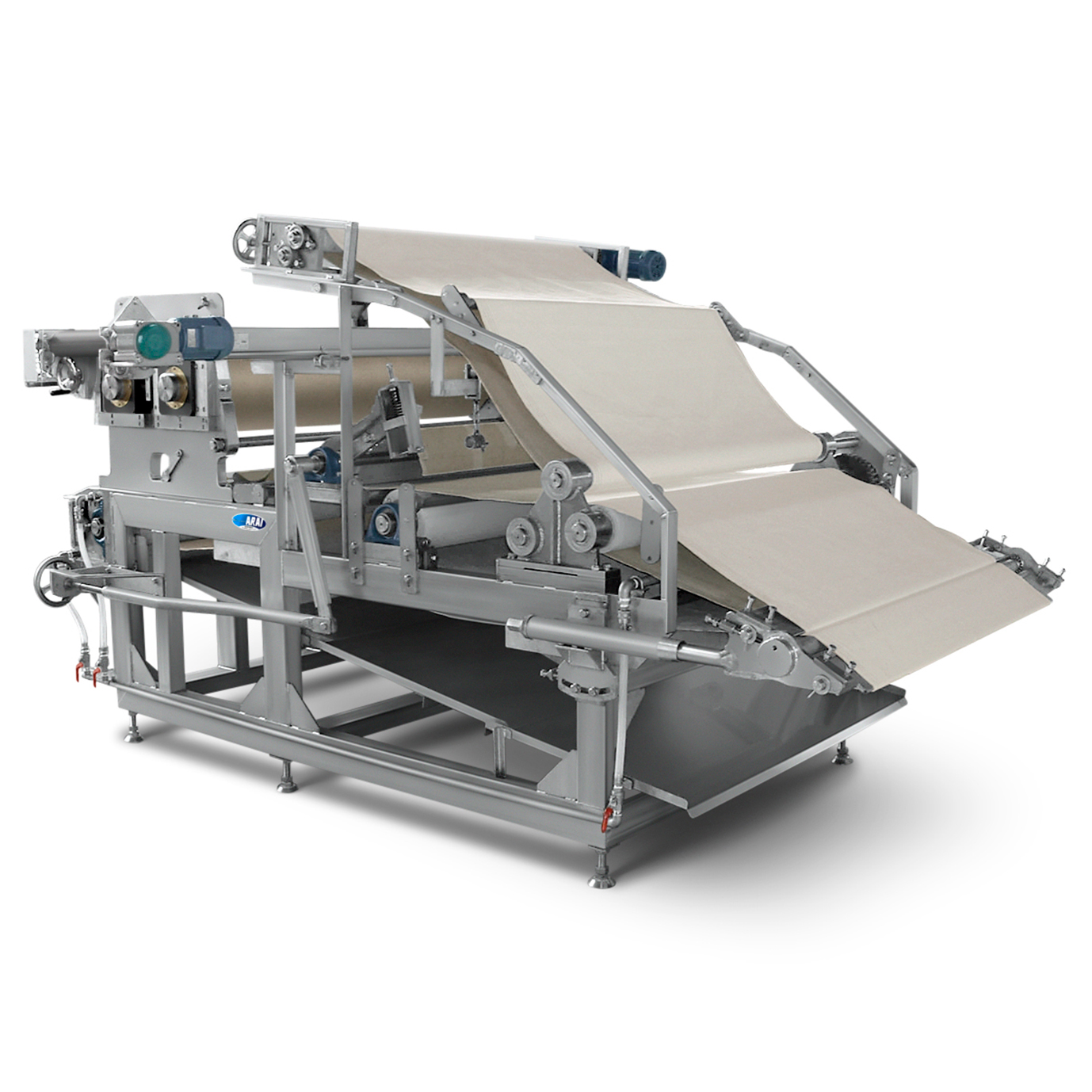

A forming machine for shaping refined mochi flour and dough into circles, triangles, squares, rectangles, and more.

With an extended roller width of 1,940 mm, this forming machine is ideal for mass production and can be integrated with continuous-type dryers, coolers, and other downstream equipment.

The material is first rolled into a sheet by a pair of opposing 260 mm-diameter rollers, then cut into the desired shape using a die cutter. The die-cut shapes and the scrap (excess margins) are separated on the lower fabric conveyor. The formed dough pieces are transferred to a net or belt conveyor while the scrap is collected. By exchanging the die cutter, a wide variety of shapes can be produced.

The drives for the lower conveyor fabric, rolling unit, and scrap collection conveyor are independently controlled, allowing for flexibility in handling variations in processing speed, material condition, and die-cutting shape.

While the standard roller diameter is 260 mm, options for 160 mm and 400 mm diameters are also available. Additionally, rollers with insulation features are available to reduce warm-up time and minimize the amount of material required for preheating.

Oil is typically used as a release agent during forming, but models compatible with water as a release agent are also available as an optional specification.

Specifications

3336W × 3336L × 1992H

6.3KW

1940mm

Related Products