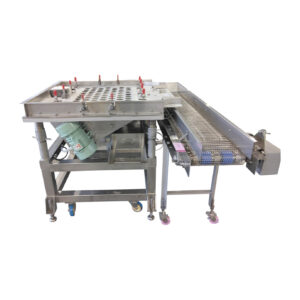

Solid products, such as rice crackers, snacks, shrimp cracker dough, and finished products, are arranged on belt conveyors, baking machines, or the net conveyors drying machines.

After the products are fed into the supply conveyor inside the machine, 1, defective items are removed in the debris removal section equipped with a vibration motor, 2. Next, the products are aligned in a gate-shaped arranging section, 3, then drawn in by a suction rotor with suction functionality, 4, and finally, they come into contact with the jam plate before being dropped onto the conveyor, 5.

To handle products of different sizes and shapes, the system can be adapted by replacing the following parts:

- Debris removal plate

- Gate

- Suction pipe

- Jam plate

Additionally, the rotor’s rotation speed is variable, allowing the system to adjust to changes in conveyor speed. This feature also helps accommodate variations in the expansion of products during baking.

Incorporating this machine into a production line not only increases throughput but also improves quality by ensuring uniformity.

The standard model is designed for a net (belt) width of 900 mm, with options available for 600 mm, 750 mm, and 1200 mm.

Specifications

1750W × 3165L × 1400H

8.12KW

1000mm

Related Products